From Duct design to installation and many challenges in between, the GSM Industrial team successfully provided a turnkey solution for one of our customers located in Bath, PA.

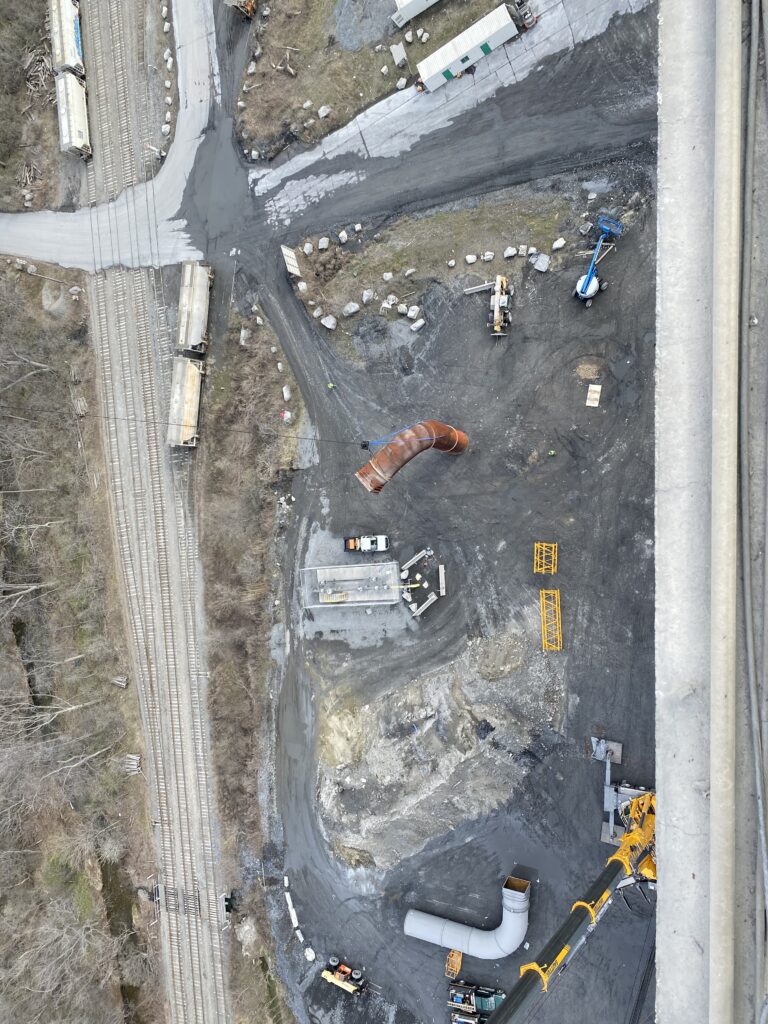

This project involved the design verification, fabrication, and field replacement of a 9’10 1/8” O.D. swan neck duct fabricated from ¼” thick AR-400 plate.

GSM Industrial did not create the original design, but it was our first time replicating the 50’ long x 35’ at 28,000 lbs. steel duct. In order to avoid having any re-work in the field, our design team verified what was missing from the original OEM drawings, and made shop corrections. By fully assembling the swan neck at our shop, our team was able complete a pre-lift at our fabrication shop to set lifting points and rigging arrangements.

To complete the project our team utilized a 700-ton crane in order to replace the old duct in one pick.

Click photo to enlarge

GSM did not create the original duct design, which posed some issues. In order to overcome this, our design team analyzed the original design compared to the installed swan neck. This way we were able to replicate the existing system, thus eliminating the need for the field to perform any field modifications. Another challenge the GSM team faced was the location of the old duct. The top of the duct was 350’ above ground. Initially, we planned on using a 500-ton crane to lift and remove the duct in multiple pieces.

After GSM was awarded the contract, we determined the safest and most efficient lifting plan was to contract a 700-ton crane to perform the pick in one piece. In order to do this, the GSM field team utilized the new duct fabrication to determine the position of lifting lugs and then performed the welding on the old duct from a crane basket 350’ in the air. Once completed we successfully removed the old duct in one piece and placed the new duct in one piece seamlessly without needing to cut and fit on site.

The customer allowed a short window during an annual outage to complete this project. After spending 80 hours detailing and analyzing, 1,000 hours fabricating and welding, and 400 hours in the field, we re-designed, removed, and installed the new duct and provided a turnkey solution for our customer. This was the 4th successful large scale duct replacement for this customer.

Our technical skills, experience, and thorough planning produced exceptional results for our customer. Our open communication, upfront design, and fabrication work were key to completing this project 3 days ahead of schedule, which allowed the customer to start back up early from their planned shutdown.

GSM Industrial is a trusted partner for OEM Installations. Learn more about GSM’s history with OEM Installations.