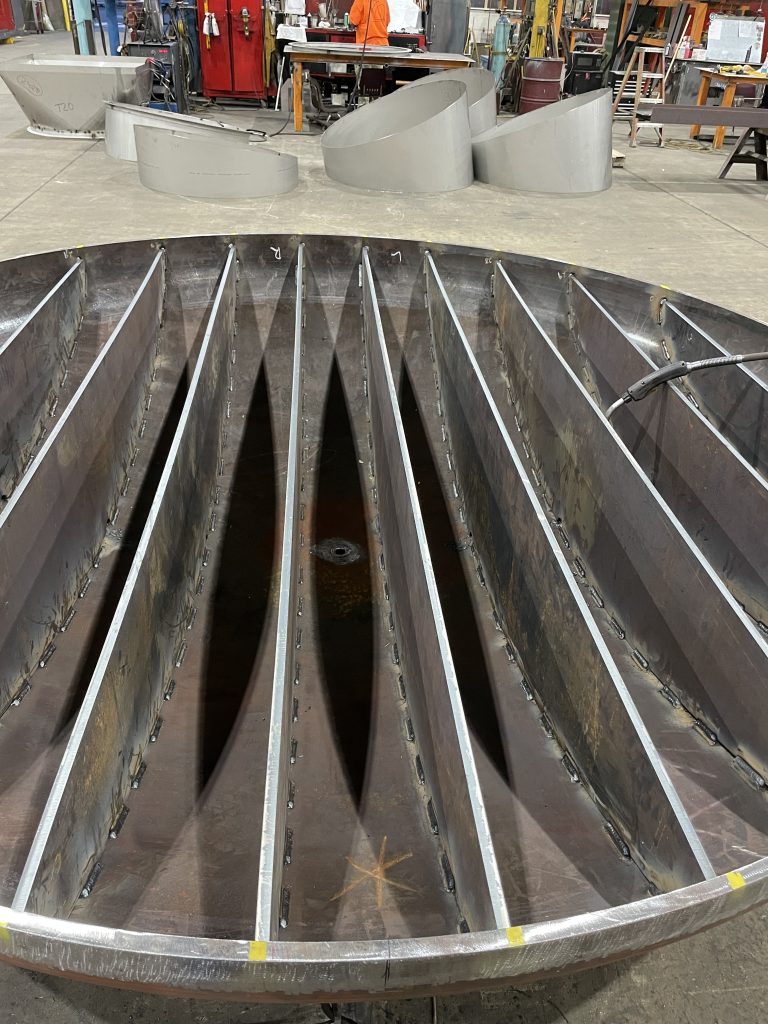

GSM Industrial, renowned for its engineering and fabrication excellence, embarked on a significant project involving the creation of two 120” Ø carbon steel cation/anion demineralizer vessels. These vessels are crucial components in water treatment processes, designed to remove impurities and ensure the delivery of clean water. The project, which is currently ongoing, showcases GSM Industrial’s commitment to quality and innovation in industrial fabrication.

The scope of the project required GSM Industrial to furnish detailed code calculations and drawings in compliance with ASME VIII DIV1 standards. Following the engineering phase, the fabrication of the vessels was carried out with precision. These carbon steel vessels, integral to the water treatment process, are designed to facilitate the removal of ions and contaminants, ensuring the purity of water for various applications, including residential use.

This project was a perfect match for GSM Industrial, leveraging our comprehensive services that include engineering, design, project management, and skilled welding and fabrication. Our team’s expertise and our facility’s advanced equipment enabled us to meet the project’s complex requirements efficiently and safely.

The carbon steel vessels fabricated by GSM Industrial play a vital role in water treatment processes. These demineralizer vessels are designed to remove unwanted ions and contaminants from water, ensuring it is safe for various uses. The clean water treated by these vessels can ultimately end up in households, providing safe and pure water for everyday use. GSM Industrial’s meticulous fabrication ensures that these vessels perform reliably and efficiently, contributing to the overall water treatment infrastructure.

If you are looking for a trusted partner to handle your complex fabrication projects, contact GSM Industrial to learn how we can bring our expertise and innovation to your next project.