GSM Industrial was contracted to fabricate and assemble critical components for three Thermal Hydrolysis Systems used in an advanced wastewater treatment facility in San Francisco, California.

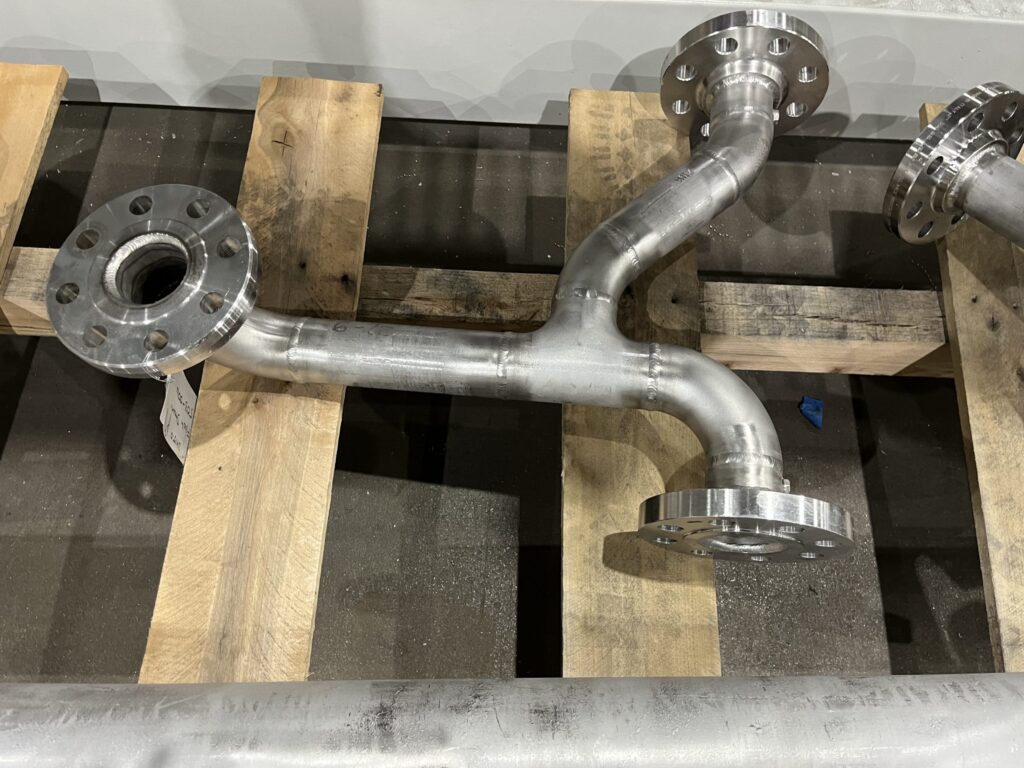

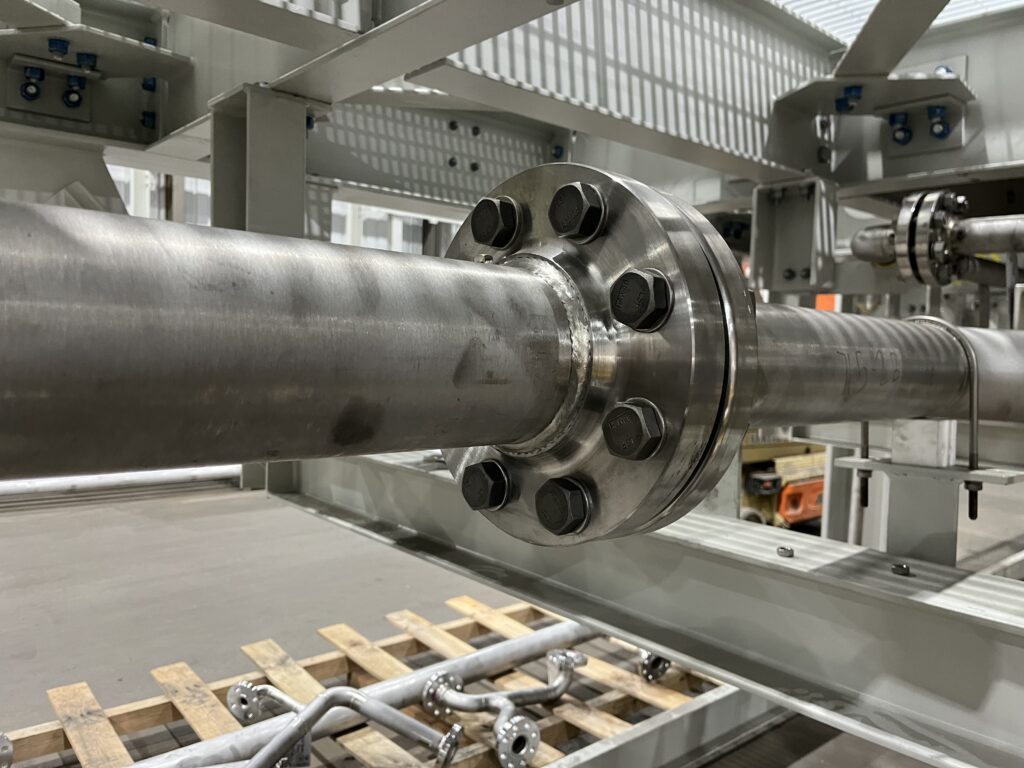

This project involved fabricating and assembling structural steelwork, staircases, platforms, handrails, and extensive 316 stainless steel process piping, including all valves and pipe supports.

Thermal hydrolysis systems play a key role in wastewater treatment, breaking down organic materials to improve biogas production and sludge management efficiency. The precision and quality of the fabrication were critical to ensuring smooth integration into the client’s existing infrastructure.

This large-scale project required overcoming several fabrication and assembly challenges:

Each of the three systems required extensive pipework, hardware, and components. Keeping every part properly tagged and organized was critical to prevent mix-ups during assembly.

Unlike many competitors, GSM Industrial had the floor space and workforce to fabricate and assemble three full systems simultaneously, allowing for efficient execution and on-time delivery.

As with many of our projects, this was a return order from a company that previously partnered with GSM Industrial.

A thermal hydrolysis system is used in wastewater treatment to break down organic material, improving sludge digestion and biogas production efficiency.

316SS is highly corrosion-resistant, making it ideal for harsh wastewater environments where durability and long-term performance are critical.

Hydrostatic testing ensures that the piping system is leak-free and meets pressure requirements before installation. Passivation further protects the stainless steel from corrosion.

We use strict quality control measures, pre-planning techniques, and expert welding procedures to meet the highest standards in industrial fabrication.

Whether you are looking for piping fabrication or prefer turnkey industrial fabrication and field installation services. GSM Industrial has a proven track record in wastewater, manufacturing, and heavy industry

Contact us to learn more about this project or get a quote.