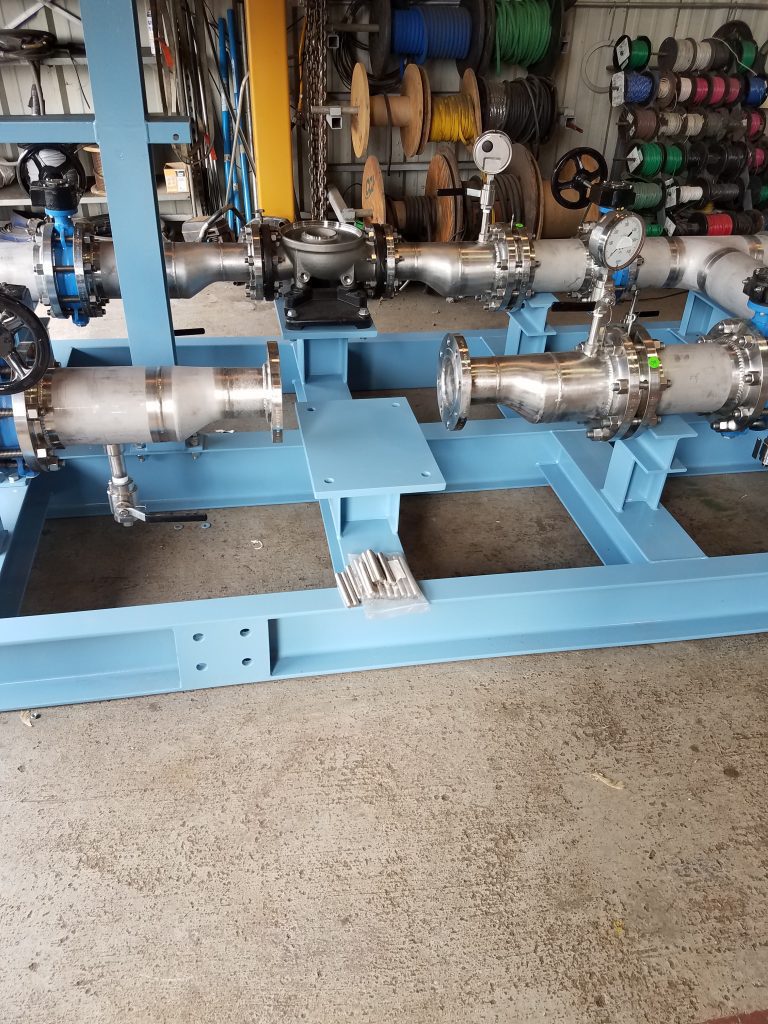

GSM Industrial successfully completed a custom ozone injection piping skid for a client in British Columbia, Canada, in late 2019. This project showcased our full-service capabilities in metal fabrication, assembly, and testing, tailored to meet precise specifications.

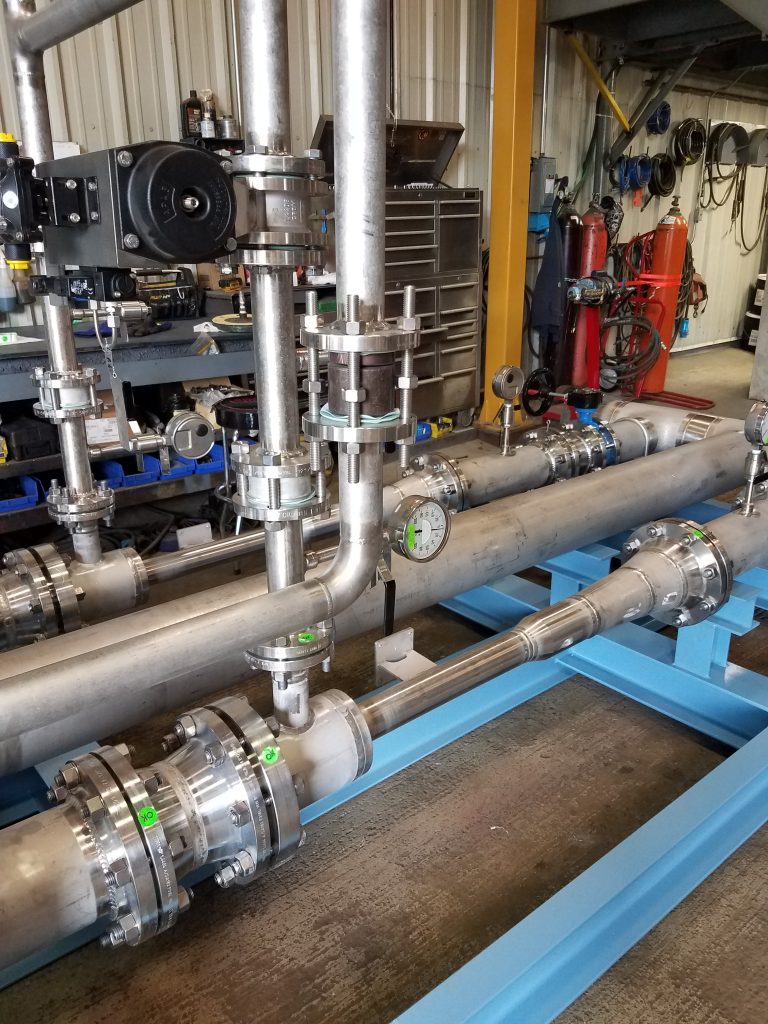

Our team worked from the customer’s design, constructing a durable carbon steel frame, blasted and painted to specification. With the frame completed, we fabricated the stainless steel piping runs, integrating components such as pumps, gauges, valves, and injectors. Our skilled technicians then assembled and tested the system for leaks using hydrostatic testing to ensure performance and reliability in the field.

Projects like this present challenges where precision and adaptability are essential. The need to connect custom fabrications with pre-fitted commercial items often reveals discrepancies in alignment, requiring meticulous adjustments. GSM’s expertise in precision fitting and adjustments allowed us to make real-time modifications without halting production, ensuring all components aligned perfectly and maintained optimal flow direction.

At GSM Industrial, we thrive in complex, turnkey fabrication projects that demand adaptability and expertise. Unlike other contractors, our team can complete these intricate builds with minimal client supervision, ensuring projects stay on schedule without compromising quality. Our hands-on approach and skilled workforce differentiate us, making GSM the ideal partner for custom industrial piping and fabrication projects.

The ozone injection piping skid exemplifies GSM Industrial’s commitment to environmental responsibility. As a critical component in water treatment processes, this skid aids in removing harmful elements from liquids, ensuring a safer and cleaner end product.

With GSM Industrial, clients receive more than fabrication—they gain a committed partner invested in achieving project success from concept to completion. Our extensive field installation services and expertise in handling complex fabrication challenges make us a preferred choice for industrial clients across North America.

Ready to discuss your next project? Contact GSM Industrial to learn more about our comprehensive metal fabrication and piping solutions.

Ozone injection piping skids are commonly used in water treatment, manufacturing, and environmental applications where clean and safe water or liquid processing is essential.

GSM Industrial employs rigorous testing, including hydrostatic testing, and our skilled technicians make real-time adjustments to ensure every component aligns perfectly and operates reliably.

Hydrostatic testing is a process that uses water to pressurize the system, ensuring it is leak-free and can handle the pressures of operational environments. This step is critical for verifying the system’s integrity before delivery.

Yes, GSM specializes in adapting and modifying designs as needed. Our team is experienced in making precise adjustments without detailed drawings, allowing projects to proceed smoothly even with custom requirements.

GSM Industrial provides fabrication services across North America and offers field installations in NJ, DE, PA, and MD, with the flexibility to travel further for the right project.